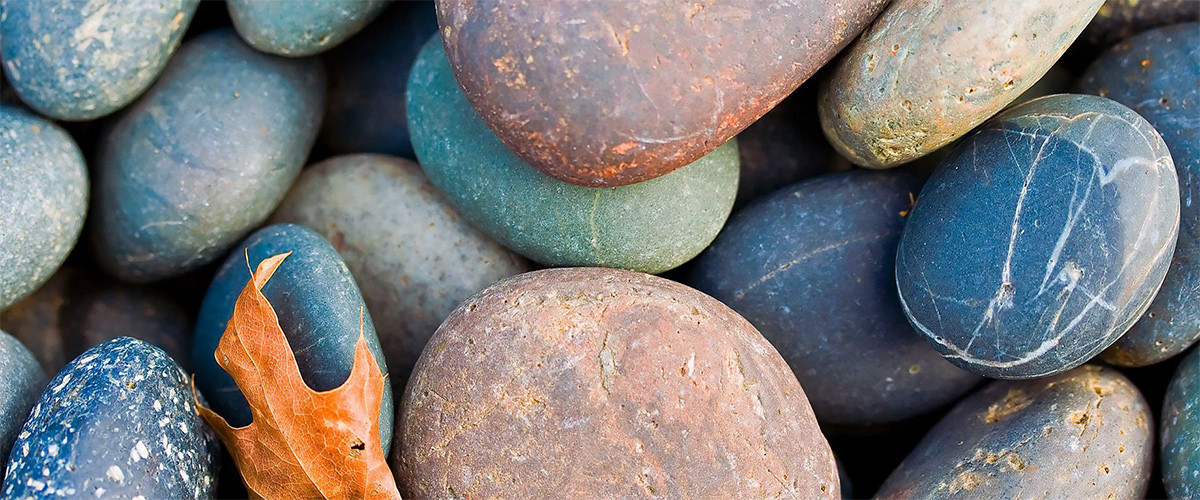

Characteristics of river pebble sand making:

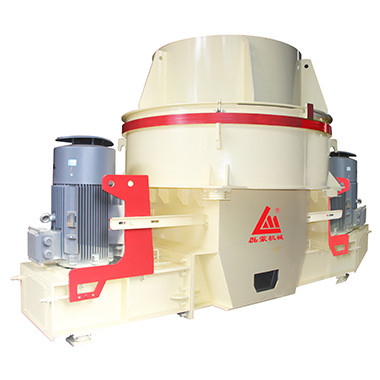

First of all, the biggest characteristic of river pebbles is high hardness and strong abrasiveness, which will cause great wear and tear on the sand making equipment. Therefore, the river pebble production line should pay attention to the rationality of the process configuration, minimize the wear cost and obtain the maximum benefit.

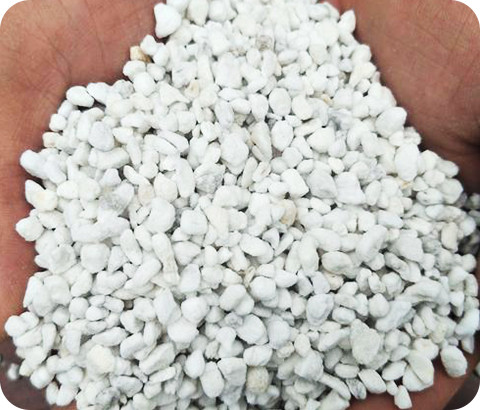

Secondly, the river pebble sand production line has to face the problem of sand and gravel cleaning. Some river sands contain a large number of mud magazines, which cause a decrease in the quality of sand and gravel. When designing the river pebble sandstone production line, the sandstone must be fully cleaned, otherwise the quality and price of the sandstone will be reduced.

Finally, the river pebble sandstone production line should pay attention to avoid repeated crushing. The raw materials themselves contain a large number of sand and gravel materials that have met the grain size requirements. For these raw materials that have reached the particle size requirements, the reasonable process is advanced screening to avoid excessive repeated crushing. , thereby reducing power consumption and wear of the wear parts of the equipment.